Evolving Packaging Solutions: Foam In Place

You’ve heard it said that change is the only constant, and the protective packaging industry is no exception. So how do we cope here at The BoxMaker? Evolve with it, of course!

Creating more advanced and sustainable solutions to meet a variety of packaging needs is always on our radar as we strive to solve problems for our customers. And luckily, working with foam allows for tons of various types, technologies, and applications to accommodate different packaging requirements.

The BoxMaker has partnered with Sealed Air to offer up one such solution. Enter Foam In Place!

So What is Foam In Place?

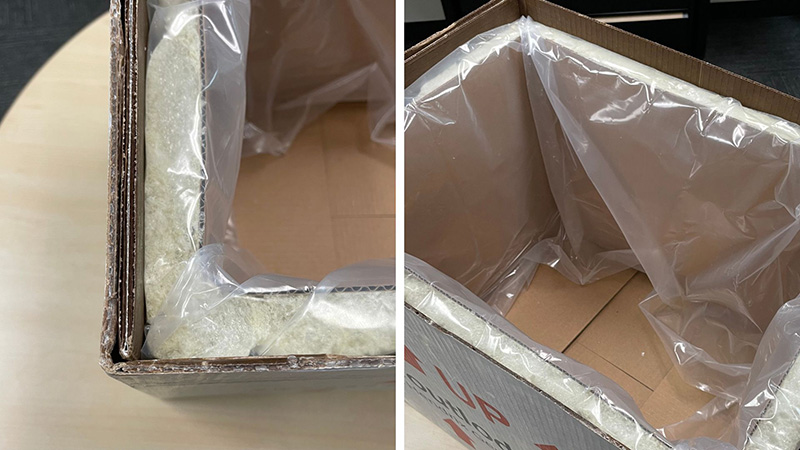

Foam In Place is a specific handling of polyurethane foam where two liquid urethane chemicals mix together and expand to create a solid substrate. This chemical reaction results in a protective, hard, foam encasing.

Foam In Place is not to be confused with flexible or memory foams, because while most urethane chemical foams result in flexible packaging, Foam In Place utilizes a unique mixing process that results in a solid chemical composition.

Would Foam In Place Be A Good Fit For You?

We know that different products require different foam solutions, so how can you tell if Foam In Place would be a good fit for your packaging needs? Some foams work best for blocking and bracing, while others are used for sustainability purposes; Foam In Place is best for cushioning. The result of the chemical reaction raises the foam to fill an entire container, encapsulating a product and immobilizing it.

One of the biggest advantages of Foam-In-Place is its ability to be customized. Because the chemical reaction forms around the desired product, every application is completely different from the last. So, companies who have a variety of different products or product lines with inconsistent packaging requirements can seriously benefit from Foam In Place technology!

Can You Give Us An Example?

Let’s use electronics to illustrate how Foam In Place works. Often times a company offers an assortment of different product bundles for shipment:

- Bundle A has a set of 2 speakers, a USB cord, and an adapter

- Bundle B has a set of 4 speakers, a USB cord, an adapter, and a remote

- You can also purchase any single item

This company needs to customize shipments to meet each customer’s unique order while ensuring the protection of their fragile products. Foam In Place offers the flexibility to personalize each shipment according to a unique order.

Now, that said, there are also methods of employing Foam In Place for consistent, uniform products. The BoxMaker is one of the few companies in the Northwest who practice molded Foam In Place.

This technique consists of injecting the two foam chemicals into a pre-made mold. The same chemical reaction takes place and the foam begins to rise, taking the form of the predetermined mold. This fabricated foam method allows us to use Foam In Place technology to create a consistent shape for companies who still desire Foam In Place protection but don’t require diverse customization.

Products with sharp edges can also gain from adopting Foam In Place technology. If you put certain foam materials around a product with a sharp edge and it drops, the edge will cut right through. Foam In Place morphs into a hard protective case that sharp-edged products won’t break through.

Subscribe

Share this post

Similar Articles

Introducing Cruz Foam™: A 100% Compostable Protective Packaging Solution

Cruz Foam is a biodegradable foam packaging solution made from upcycled food waste, offering an sust …

Exploring F-Flute: A Game-Changer in Retail Packaging

Learn about the features of f-flute corrugated and the benefits this material delivers to retail pac …

Introducing Hexpand: A New Sustainable Protective Packaging Solution

Hexpand is a new retention and suspension packaging solution offering earth-friendly product protect …