Flexo vs. Digital Print for Labels: Which Should You Choose?

Gutenberg’s creation of the printing press in 1440 is often considered one of the most important inventions of all time. The printing press opened the doors of rapid production and made possible the wide distribution of written materials and information, which for the first time could be produced in a relatively high volume of copies.

From a technological standpoint, we’ve come a very long way since Gutenberg when it comes to publishing. However, the printing press has not lost its importance in today’s society, especially when it comes to product promotion. Brands rely on modern printing presses to inform, attract, and engage with customers through packaging.

As a key element in packaging, product labels help distinguish one brand from another. When produced effectively, labels can provide a branded experience and influence customers to make a purchase.

Two common print production methods used to produce custom product labels are flexography (often referred to as flexo print) and digital printing. While both methods have their advantages and drawbacks, brands must consider several key factors when choosing the print method best suited to their project.

Flexography: How Does It Work?

Flexo print has had a long history in packaging, with the first flexo-type printing presses dating back to 1890. While flexo saw minimal commercial success in the decades following, the process took off in the late 20th century with technological advancements in specialized inks, dies, and plate making.

Flexo operates much like a giant rubber stamp. Before label production begins, custom print plates must be manufactured for the specific project. The plate features raised rubber or photopolymer molds that depict the desired artwork. Once assembled on press, ink is applied to the raised areas of the plate which then rotates on a cylinder at high speeds to transfer the image to the label substrate. Each color needed to print the desired artwork requires a separate print plate that must be purchased and factored into the price of the packaging job. Multi-color jobs require the purchase and set up of multiple print plates, and individual flexo presses have a set number of maximum plates they can utilize.

The benefit of flexo printing lies in the high volumes of impressions that can be achieved once the initial machine setup is complete. The high-speed production in flexo typically allows this method to be more affordable for large label orders, compared to other printing methods.

In addition, flexo can utilize a wide range of inks on a variety of substrate options, such as metallic ink and heat-sensitive surfaces. For brands that require color precision (think: Coca Cola), flexo uses the standardized color system Pantone® to achieve exact color matching.

Because the flexo process requires the production of custom print plates, tooling, and additional setup time, it may not be the most cost-effective method for small label order volumes or short run printing.

The Science Behind Digital Printing

The first digital printing press was developed in 1993 by a company called Indigo, now owned by tech giant HP. What was once regarded as the new kid on the block, digital print has quickly advanced as an increasingly adopted print method in the packaging industry. In fact, digital print accounts for roughly 18% of all print.

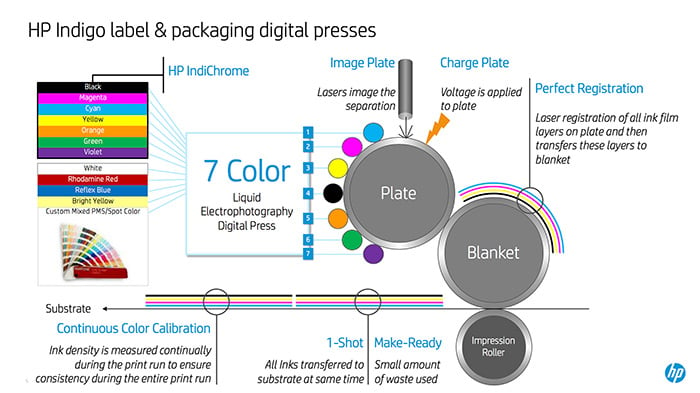

Digital printing for labels on HP Indigo presses operates in a similar fashion to flexography, without the need for print plates. Instead of applying ink to a plate, specially developed inks are electrically charged and held to a blanket. When the blanket comes into contact with the label substrate as it moves through the press, the charge on the ink is reversed and the image is transferred to the label or paper.

As a result, digital print supports faster speed-to-market and turnaround times for label production. Brands that frequently integrate short-run or seasonal marketing campaigns into their packaging often prefer digital print over flexo for their label applications.

Image Source: HP

Advancements in digital print continue to push the technology to deliver the highest quality print at a comparative speed to traditional print methods, such as flexo. Other benefits include no minimum or maximum order volumes (depending on your supplier), variable print capabilities, full CMYK color printing, and potential cost-savings due to the lack of print plates and reduced setup time.

Additionally, innovative suppliers are increasing the types of specialty inks and substrates available for digital print. HP recently released a series of fluorescent inks for their Indigo press line, and announced the release of ElectroInk Silver in 2018. Many label stock suppliers have released digital-specific product lines and continue to add new and unique substrate options for labels, including felt, velvet, wood veneer, and many more.

Which Print Production Method is Better for Labels?

The answer to this question depends on whether or not your label project would benefit from any of the advantages of digital print, the volume of your order, and your budget.

The price per label for digital print vs. flexo can be very different depending on the volume of an order. With digital, the cost per label remains is basically the same throughout the run. With flexo most of the cost lies upfront in the machine setup time and print plate manufacturing, so the more labels you order the less expensive each label becomes as that cost is distributed over a higher and higher volume. Thus, for very high-volume orders (tens of thousands and more), flexo will most likely offer a better price.

Digital print makes personalization easy.

Digital print makes personalization easy.

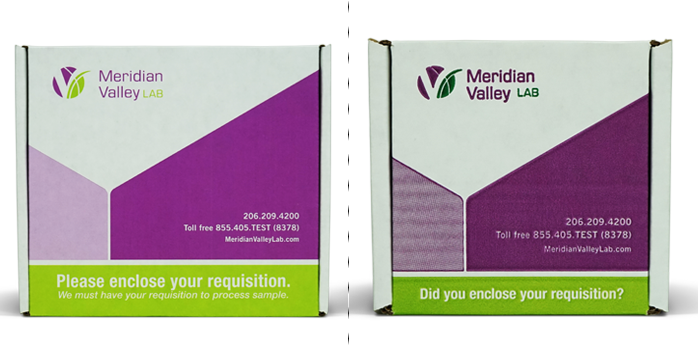

Brand’s must also consider what today’s consumers demand from product packaging. In a world that is becoming increasingly personalized, digital print empowers brands to custom-tailor their products down to the individual consumer with relative ease compared to the traditional flexo print method.

If you’re running a large label order for a product that will be on store shelves across the country, flexo is a practical choice. If you have a seasonal product, desire any level of variable or personalized graphics, or have specific volume needs, digital print is a great option for your project.

Ultimately, a brand must comprehensively understand their packaging needs and requirements in order to make an informed decision.

Subscribe

Share this post

Similar Articles

Brand Color Management: How Can G7 Certification Help?

The BoxMaker achieved G7 certification across our wide-format digital printers. Learn how partnering …

Making the Upgrade from Flexo to Digital Print

Switching from flexo print to digital print is no easy decision. Here are three reasons to make the …

Spot Color vs. CMYK for Packaging Design – What’s the Difference?

Choosing spot color vs. CMYK color in your packaging design artwork file can impact the final produc …