How to Measure a Corrugated Box

When it comes to packaging, one size doesn't fit all. If you have an existing box on hand that you want your packaging manufacturer to reproduce (and they didn’t design it in the first place), you will need to communicate your desired box dimensions to them.

However, knowing how to accurately measure a box isn’t as straightforward as it may seem. A simple mismeasurement can result in a costly and time-consuming setback to your project.

Let’s take a closer look at how to properly measure a common RSC box using score-to-score dimensions so that you can be confident in the outcome of your custom-manufactured packaging.

Corrugated Boxes: Three Sets of Dimensions

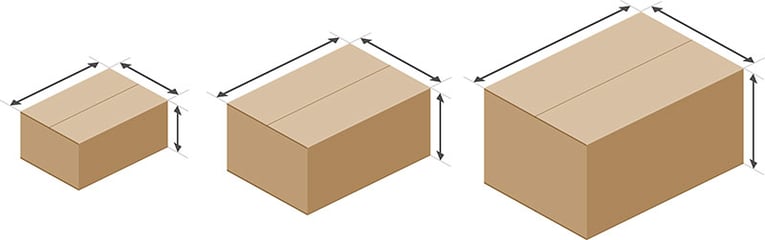

The size of a corrugated box is always expressed by three dimensions: length, width, and depth, or L x W x D. Length is always the longest side of the box with a flap. The width also has a flap, but this side is shorter than the length. The depth relates to the area between the top and bottom openings of the box (the height).

How you measure your box's length, width, and depth matters. Corrugated boxes have three sets of dimensions: interior, exterior, and score-to-score.

Interior Dimensions

The interior dimensions of a corrugated box reflect the amount of usable space in the box when assembled. The interior dimensions are the industry standard measurement used to determine the fit of the product that goes inside.

When ordering boxes, the measurements you see listed by default relate to the interior dimensions. For example, a 10” x 10” x 6” box will have 10” of space from wall to wall (length and width), and 6” of space from bottom to top (depth).

Interior dimensions are critical when finding a stock box to fit your product or designing a custom box from the ground up. However, if you’re trying to reproduce an existing box, they’re not the most accurate set of dimensions to communicate to your packaging manufacturer.

Exterior Dimensions

A corrugated box's exterior dimensions reflect the box's full size when assembled. These can be helpful to know for shipping and inventory purposes. For example, our 10” x 10” x 6” box from above, when expressed by its exterior dimensions, may measure 10 3/8” x 10 3/8” x 6 5/8” fully assembled.

Exterior dimensions only tell us the final size of the box, but they don’t tell us anything about the thickness of the material that the box is made of. Therefore, they are also not the most accurate set of measurements to provide to your packaging partner.

Score-to-Score Dimensions

Using score-to-score dimensions is the most accurate way to measure your box if you are trying to replicate it with your packaging manufacturer. Score-to-score dimensions measure the distance between the “scores” of your box (where your box folds) and account for the thickness of the corrugated board, also known as material allowances.

You will notice that score-to-score dimensions fall somewhere between your box’s interior and exterior dimensions.

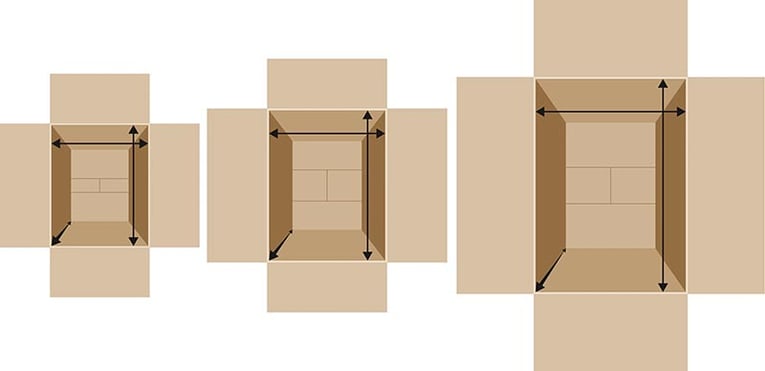

Measuring the Score-to-Score Dimensions of a Box

To measure the score-to-score dimensions of a box, position the unglued box in front of you, with the inside of the box facing up. Use a ruler to draw a straight line along the exact middle of the score lines where the box folds. Mark the two scores that make up the box's length, width, and depth, creating four panels. It is best to use panels 2 and 3 when taking your length and width measurements.

Use a tape measure to measure the length, width, and depth of your box by measuring the distance between the marked scores. Your measurements should be in inches, rounded to the nearest 1/16”.

When communicating your measurements to The BoxMaker or your packaging manufacturer of choice, be sure to tell your Sales Representative that you are giving them score-to-score measurements.

Box Measurement Considerations

Remember that the score-to-score measurements when the panels are flat are not the actual useable space in a box. Once the box is folded and the flaps are in place, some of that space is occupied by the thickness of the material folding and creating the corners. The flaps also require some space when they are folded down. For determining usable box space, go by interior dimensions. If you have provided your packaging manufacturer with score-to-score information, they can calculate your interior dimensions.

When in doubt, choose a custom packaging manufacturer who can support your project with a talented and experienced structural design staff. The BoxMaker’s award-winning team of designers are specially trained to produce custom boxes that perfectly match your product’s size and specifications, or to reverse-engineer your existing packaging to accurately replicate your box. Contact our Packaging Advisors and let us help you get started on your next custom packaging project.

Subscribe

Share this post

Similar Articles

Folding Carton vs. Corrugated Packaging for Retail

Folding carton and corrugated are used in retail packaging. But what’s the difference, and when shou …

FOL vs. RSC Boxes

When it comes to corrugated shipping boxes, there are two you’ll likely consider: RSC and FOL. Which …

Why is Packaging Design Important?

Packaging design is a vehicle for your brand, marketing efforts, sustainability goals, and operation …