Packaging Overruns & Underruns Explained

When it comes to the custom manufacturing of high-volume packaging orders, minor fluctuations in the final number of units produced against the exact volume that was ordered is a common event. In certain circumstances, you may receive a small additional quantity on your order, otherwise known as an overrun. Conversely, if you receive less than you ordered, this is known as an underrun. The fact is, overruns and underruns are a normal occurrence in the manufacturing industry when producing hundreds and thousands of boxes at a time.

While this aspect of the production process can understandably be a source of confusion for packaging buyers, it’s worth understanding so that you can factor in the possibility of a flux in your final order volume when budgeting costs and assessing inventory.

When speaking about custom corrugated packaging, the industry standard for overruns and underruns allows for a + or – 10% discrepancy.

This fluctuation in final order count, no matter how small, can create real issues that impact your business and are problematic when not planned for. An excess of inventory due to an overrun can possibly affect storage space. On the other hand, an inventory shortage can delay product shipment.

Why Do Overruns & Underruns Occur?

You may be wondering, “Why do manufacturing overruns and underruns occur?” Here’s an analogy to consider: Imagine you’re riding a bicycle downhill, at full speed. It’s not wise (or safe) to stop immediately. You must gradually hit the brakes before you can fully stop.

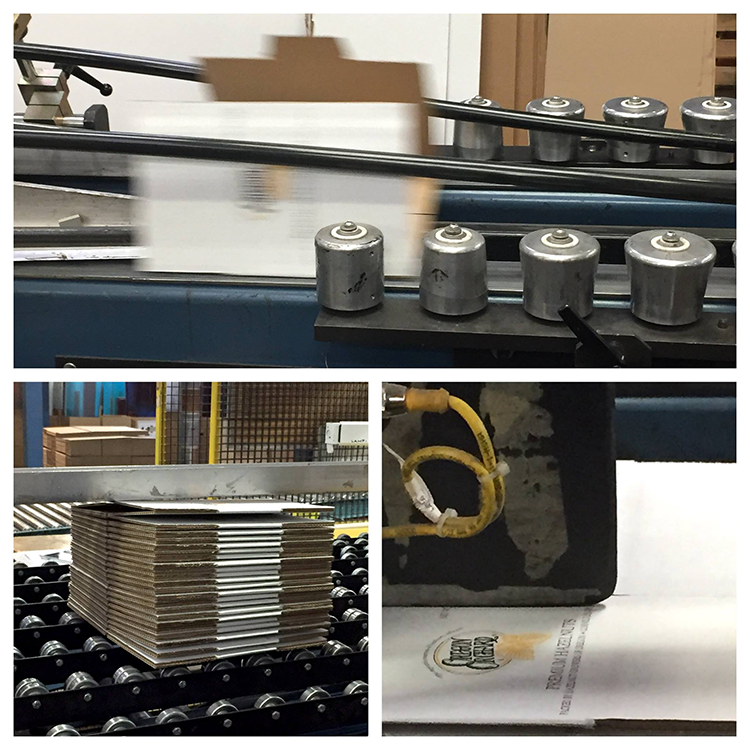

Due to the high-speed process of custom packaging manufacturing, complex, large-scale corrugated presses are unable to stop on a dime. Similar to riding downhill on a bicycle, the presses need time to come to a halt. As a result, there can be a small shortage or overage of product in the end.

Planning for and Preventing Underruns

Not having enough packaging on hand when it’s time to pack and ship your product can be a significant hurdle when working against a deadline. Your packaging manufacturer can help you plan ahead for the possibility of an underrun. If receiving an exact volume order is crucial to your project, let your Packaging Advisor know. This alerts them to work with their internal team to account for your specific volume needs. This may require ordering additional material or planning for extra labor, so typically there is a cost attached.

How Digital Print Production Can Help

If it’s appropriate for your project, digital print production can dramatically reduce the opportunity for overruns and underruns in your packaging order. Digital printing is calibrated so that the first print is identical to the last, and the presses are able to produce boxes and retail displays in exact quantities. Compared to traditional litho lamination, digital printing requires no print plates and reduces setup time, therefore producing less waste and less expense for you.

Choosing the Right Packaging Partner

It’s important to understand that overruns and underruns can and do happen in custom manufacturing. However, every effort is made to only produce the quantity that has been ordered to the best of your manufacturer’s abilities.

At The BoxMaker, our Packaging Advisors are committed to transparency throughout every step of the process. If your order may be subject to an overrun or underrun, our team will alert you in advance and provide recommendations for the best course of action.

Subscribe

Share this post

Similar Articles

Spot Color vs. CMYK for Packaging Design – What’s the Difference?

Choosing spot color vs. CMYK color in your packaging design artwork file can impact the final produc …

'Tis the Season: Holiday Packaging Trends to Watch Out For

Now is the time when brands reveal their festive holiday packaging. Discover 3 festive packaging tre …

How to Calculate the Cost of Packaging

Learn how to calculate the cost of packaging for your business. Download our free packaging budget p …