Why Should Brands Use Retail-Ready Packaging (RRP)?

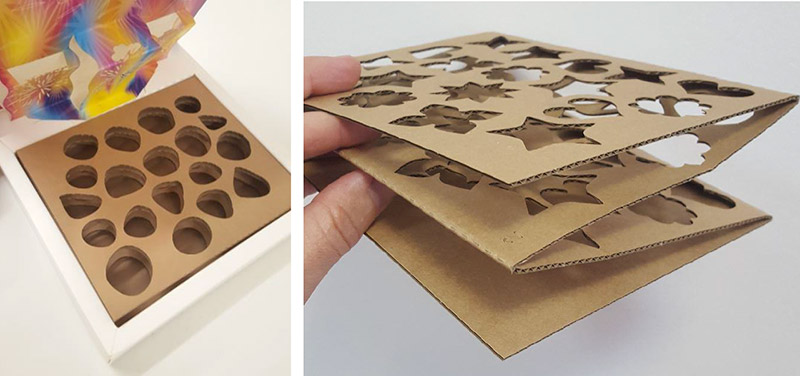

The demand for retail-ready packaging (RRP) is increasing, and brands across the retail marketplace are starting to make the switch. Also known as shelf-ready packaging, RRP refers to self-contained secondary packaging that is optimized for stocking and display at big box or club stores. Predominantly made of corrugated, many different types of RRP options are available, including pallet displays, case stackers, and counter displays.

When properly designed, RRP can hold individually packaged products, eliminating the need for store employees to unpack and individually display each product on shelves. For retailers and suppliers alike, using RRP provides a major opportunity to improve supply chain efficiencies and generate sales at the point-of-purchase.

Why Use Retail-Ready Packaging?

Operational costs at retail stores come in all shapes and sizes, and retailers are always trying to find ways to trim them down wherever possible. In the past several years, retailers have started catching on to an area where operational costs can be significantly reduced: labor. In fact, 25 percent of a retailer’s costs are related to labor, including finding products in stock, displaying, and disposing of leftover packaging.

Taking products directly from the truck to the shelf eliminates the need to unpack individual items. For example, Walmart suggests that the employees should be able to remove RRP from the shipper and place it on the shelf ideally in just two “touches.” This in turn saves time and money on labor costs. Retailers also enjoy RRP because it results in cleaner stores for customers, fewer shelf gaps, and can trigger impulse purchases.

However, make no mistake — RRP doesn’t just benefit the retailers. The simplified transition process from warehouse to shelf means better in-stock availability for suppliers. Using RRP also enhances suppliers’ positioning and visibility at the store level, thus increasing the chance for sales. On the consumer side, RRP helps make the transition from shelf to shopping cart easier by enhancing the shopping experience.

Characteristics of an Efficient Retail-Ready Packaging

Retail giants like Walmart, Costco, and Kroger have established their own RRP guidelines for suppliers to help standardize their shelves — all of which follow similar principles known as “The 5 Easies.” Here are the 5 common requirements for RRP:

Easy to identify: To make the product easy to find in both the warehouse and on the shelf, the front panel of RRP must provide clear text and graphic information such as branding, product name, SKUs, etc.

Easy to open: RRP must be easily opened in-store without the need for additional tools, such as box cutters or knives. It typically features clear opening instructions and easy tear-offs to allow for smooth edges when assembled. However, it must also be sturdy enough to withstand the transport and supply chain process without damaging the product inside.

Easy to stock: Stocking and merchandise can be a time-consuming and labor-intensive process. RRP is designed to be easy to stock onto shelves, minimizing time and physical effort for store employees. For example: handles integrated into the packaging can help employees with shelf placement into an allotted space.

Easy to dispose: The breakdown and disposal of RRP should require a minimal amount of time and storage space. It should also be recyclable or reusable to minimize packaging waste.

Easy to shop: Once the consumer has found the product that they want, they must be able to easily remove it from RRP, or placed back, without any difficulty. The packaging design must also clearly label product information, such as food allergies and expiration dates. Essentially, RRP should make the shopping experience as simple and straightforward as possible.

Benefits of Retail-Ready Packaging:

RRP offers a variety of benefits over traditional retail packaging for retailers, suppliers or brands, and consumers. Here are the 4 main benefits of utilizing RRP:

Benefit #1: It Forces Brands to Think Holistically

Primary package design can majorly impact secondary packaging and pallet optimization. By considering how the packaging will hold up throughout its journey — from warehouse to shelf — brands can avoid costs down the line in terms of product damage.

Benefit #2: Brands Can Avoid Stock-Outs

Quick and easy loading helps brands avoid stock-outs, or when a retailer runs out of inventory for a specific product. More time on the shelves means more brand exposure, as well as more sales.

Benefit #3: RRP Can Help Decrease Packaging Waste

Efficient packaging that aims to decrease waste means brands can spend less on material in the first place, and retailers spend less time and money when disposing the material at the end of the product lifecycle.

Benefit #4: RRP Augments Product Presentation

When brands intentionally design their packaging to be sturdy and stackable on the shelf, it ensures that their product won’t lose aesthetic integrity. That way, brands avoid their product becoming a jumbled heap as it sells down.

Getting Started with Retail Ready Packaging

In conclusion, Retail Ready Packaging (RRP) has emerged as a game-changer in the competitive retail landscape. By streamlining shelf stocking, bolstering product visibility, and enhancing the customer experience, RRP effectively addresses the needs of both retailers and shoppers. By adopting RRP, businesses can enjoy increased sales, reduced labor costs, and a stronger brand identity.

If you're ready to create a seamless, efficient, and memorable retail experience that keeps customers coming back for more, contact The BoxMaker and tell us about your project.

Subscribe

Share this post

Similar Articles

Folding Carton vs. Corrugated Packaging for Retail

Folding carton and corrugated are used in retail packaging. But what’s the difference, and when shou …

Exploring Augmented Reality for Product Packaging

Augmented reality (AR) allows brands to add a whole new dimension to packaging, labels, and displays …

How to Eliminate Plastics from Your Corrugated Packaging

Consumers expect eco-friendly packaging choices. Here are 5 ways that dieless finishing can be lever …