REFT vs. RETT: Which is the Right Box Style for Your Brand?

There’s a wide variety of corrugated box styles available for shipping and retail packaging. Two common styles you’ll likely come across are Roll End Front Tuck (REFT) and Roll End Tuck Top (RETT) boxes. At first glance, these two styles may appear to look and function similarly. However, brands are often surprised to learn that each of these box styles offers their own unique advantages.

Understanding the differences between the REFT and the RETT can help you make an informed decision on which box style might perform better for your brand.

Roll End Front Tuck (REFT) Boxes

The REFT box features rounded flaps on the lid that are engineered to smoothly tuck into the front of the main body. The primary purpose of the front flaps is to prevent the lid from unexpectedly opening. The front flap feature is designed to enhance product protection as the box moves through the supply chain process. Additional dust flaps can be added to the sides of this box style to increase structural strength. The dust flaps tuck into the box to help keep dust and other particles from entering and damaging the product as the package travels through distribution, shipping, and delivery.

Additional dust flaps can be added to the sides of this box style to increase structural strength. The dust flaps tuck into the box to help keep dust and other particles from entering and damaging the product as the package travels through distribution, shipping, and delivery. Brands enjoy the REFT box for the presentation value, available branding real estate, and reusability. From an eCommerce or retail perspective, REFTs provide a great unboxing experience for the end consumer. In fact, the REFT with dust flaps is the #1 style of choice for subscription box packaging. One consideration to keep in mind is that the added flaps require slightly more time and effort to fold when assembling your box.

Brands enjoy the REFT box for the presentation value, available branding real estate, and reusability. From an eCommerce or retail perspective, REFTs provide a great unboxing experience for the end consumer. In fact, the REFT with dust flaps is the #1 style of choice for subscription box packaging. One consideration to keep in mind is that the added flaps require slightly more time and effort to fold when assembling your box.

Roll End Tuck Top (RETT) Boxes

Like opening up a treasure chest, the RETT box opens and closes with a simple tuck to the inside of the box. This style has a connected lid and front panel with a locking flap that goes in between two side panels. Compared to the REFT box and other similar styles, the RETT uses a minimal amount of materials, which translates to cost-savings over time. However, unlike the REFT with its locking flaps, the RETT requires tape or an additional label to seal the box.

Here are the advantages of using RETT boxes:

Benefit #1: Efficient Loading During Production

Since no locking feature secures the box lid in place, RETTs support efficient loading. In a production line, employees can quickly load product into the box without having to fold in additional flaps.

Benefit #2: Great for Industrial Uses

Thanks to the double layer protection on the bottom and sides, the structure of the RETT is designed to withstand the rough and tumble shipping journey. As a result, this style is often used for industrial purposes, such as master packing or kitting. Kitting is the process of packing separate but related items together and placing them in a larger shipping box.

Benefit #3: Easy to Open for End Consumer

RETT boxes assemble without the need for glue, tape, or staples. For the end consumer, this box style is easy to open with minimal effort — no additional cutters or tools required.

Which Box Style is the Right Choice?

REFTs and RETTs are only two of many standard box styles available for shipping and retail purposes, in addition to custom packaging solutions. Work with a dedicated Packaging Advisor to determine the best box style for your product based on the unique demands of your business.

To learn more about common box styles and their applications, download The BoxMaker’s free Guide to Corrugated Box Styles to explore your options today.

Subscribe

Share this post

Similar Articles

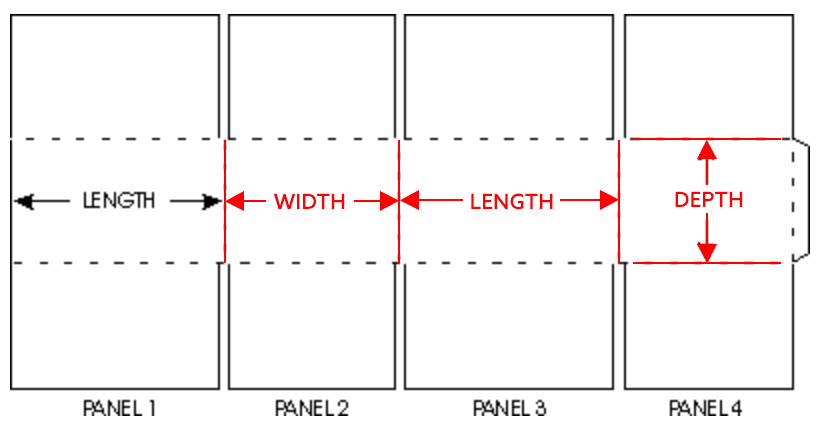

How to Measure a Corrugated Box

To produce an accurate replica of a custom corrugated box, it’s important to know how to measure the …

FOL vs. RSC Boxes

When it comes to corrugated shipping boxes, there are two you’ll likely consider: RSC and FOL. Which …

Make it POP: The Art of Retail Displays

Learn the art of creating impactful point of purchase retail displays that grab consumer attention a …