TCO: Understanding the True Cost of Packaging Inventory

Calculating the total cost of packaging involves more than just considering obvious expenses like materials, labor, and shipping. Hidden costs also play a significant role.

Understanding and Evaluating Total Cost of Ownership

To accurately assess the cost of custom packaging, it's crucial to consider the total cost of ownership (TCO).

For packaging, TCO considers all up-front costs as well as any hidden costs associated with your packaging inventory, including:

- Materials and Manufacturing: The direct expenses involved in creating the packaging.

- Labor: Costs associated with handling and preparing the packaging.

- Shipping: Expenses incurred during the transportation of packaging.

- Warehousing: Costs related to storing unused packaging inventory.

- Damaged Inventory: Additional costs incurred to replace damaged packaging.

By accounting for all these factors, brands can make more informed decisions about their packaging strategies and come up with ways to reduce costs.

What Unused Packaging Inventory is Costing You

Reducing warehousing is one of the most effective ways for brands to reduce carrying costs incurred from unused packaging inventory. Minimizing the amount of space taken up by pallets as well as the length of time that each pallet spends on the warehouse floor will significantly reduce TCO.

To better understand the relationship between packaging inventory and total packaging cost, let’s take a closer look at the true cost of warehousing a single pallet of packaging:

Cost Breakdown of Warehousing a Single Pallet

To warehouse a typical 4' x 4' pallet (16 square feet), the costs can be substantial. If you store it in an owned property, the monthly cost is approximately $16 ($1 per square foot). For a rented property, the cost ranges from $32 to $48 ($2 to $3 per square foot).

This includes the cost of the building, energy for climate control/lighting, and labor.

Other cost considerations include:

- Stacking/racking the pallets – This increases the utilization of space and reduces overall cost. However, you only recapture those cost savings with a narrow warehouse aisle configuration instead of a standard aisle configuration.

- Labor - Additional labor costs to move the pallet as needed.

- Risk of damage - Cost of potential loss due to dust, dirt, grime, or packaging damage from being bumped and moved.

The longer that a pallet of unused packaging remains on the warehouse floor, the longer these costs will add up, which can result in a significant increase to TCO.

Impact of Packaging Overstocks on Cashflow

Excess packaging inventory ties up cash that could be better utilized elsewhere in your business. With current borrowing interest rates exceeding 8% or 9% depending on your level of risk, it’s vital to minimize unnecessary stock to avoid unnecessary costs.

Minimize Risk and Maximize Cash with Inventory Optimization

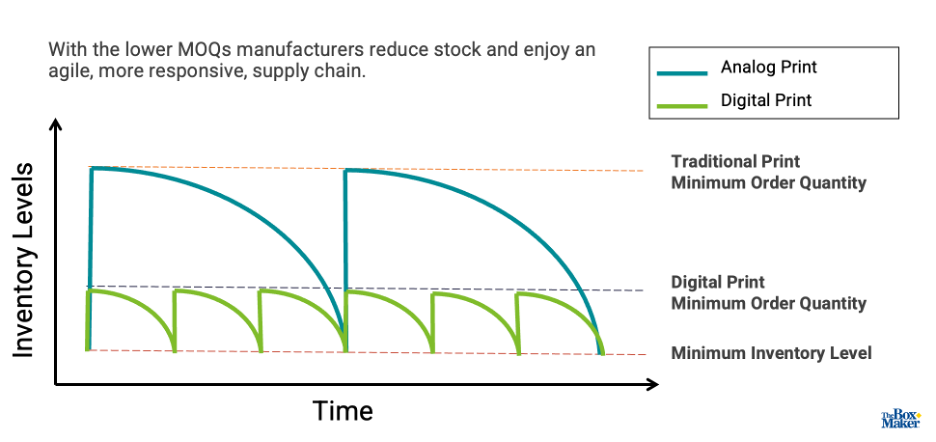

Conventional box production methods are designed to produce a high volume of identical units. These analog methods of custom box printing and finishing include flexography, litho-lamination, and die cutting. Because of the raw materials and labor needed for setup in a conventional print/finishing job for custom corrugated packaging, custom box manufacturing and procurement methodologies are built around high-volume production.

The historic focus by packaging buyers on the direct cost of the box per unit has led to a loss of focus on all the indirect costs that come with it. From warehousing mass quantities of packaging to production overruns and tying up cash in unused inventory, a box that on paper costs a matter of cents actually incurs a much greater cost to your company.

Opting for short-run or lower-volume production options like digital print might slightly increase the cost per unit on paper, but these methods empower companies to optimize inventory and streamline its management. This approach frees up cash, saves warehouse space, and minimizes packaging obsolescence.

Now, buyers can place orders more frequently in quantities that suit the current needs of their business, preserving the quality of their packaging purchase.

More Ways to Reduce Costs

Aside from optimizing your inventory, you can also reduce costs by 1) Utilizing a localized supply chain, and 2) Working with an all-in-one supplier.

Using a localized supply chain can greatly enhance a company's agility and lower the overall costs incurred by logistics, labor, and tariffs if you are working with a vendor overseas. Businesses can also streamline their operations and reduce the number of suppliers they need to manage by choosing to work with an all-in-one supplier to handle all packaging needs.

This consolidation allows your team to focus on their core activities by reducing the number of details they need to keep track of. Time saved means money saved. For example, reducing the number of purchase orders (POs) issued to multiple suppliers can lead to significant cost savings, as each PO can cost several hundred dollars to process when you consider activities like cutting the PO, receiving goods, managing inventory, and handling invoices.

Partner with The BoxMaker to Optimize Your Cashflow

At The BoxMaker, we excel in our product quality and delivery performance, as reflected in our outstanding lead time. Instead of forcing our clients to stockpile inventory, we leverage digital production technologies to emphasize agility and responsiveness to meet your needs on time. As both a custom packaging manufacturer and distributor, our comprehensive solutions can also streamline your business operations by handling all your packaging needs.

Contact our Packaging Advisors today to start using digitally printed packaging to optimize inventory and free up cash to reinvest in your business.

Subscribe

Share this post

Similar Articles

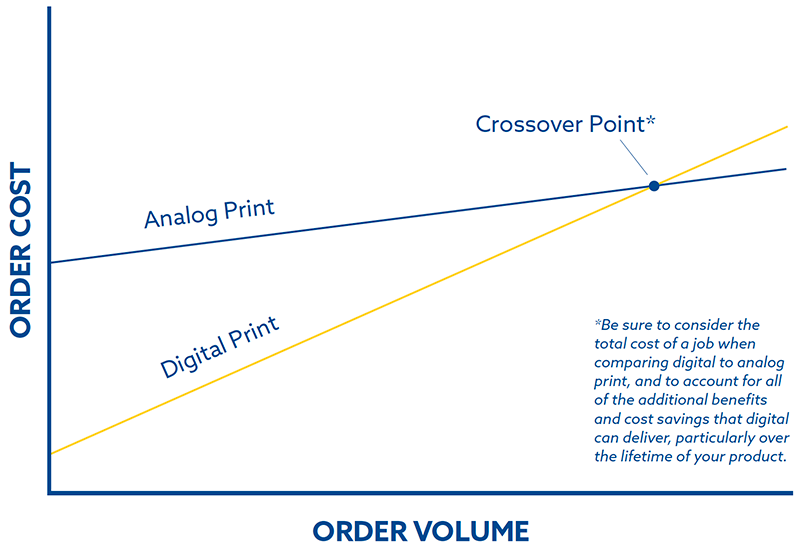

Understanding the Conventional vs. Digital Print Crossover Point

The crossover point at which conventional print is more cost-effective than digital print is changin …

The Environmental Cost of Damaged Shipments

Products damaged during shipment have a significant cost to the business. Environmental impact can b …

Costco’s New Packaging Requirements and the Impact to Brands

Your guide to Costco’s 2023 packaging requirements and sustainability commitment. A summary to help …